Stiùireadh Sreath DFM Rod pìoban siolandair adhair alùmanum

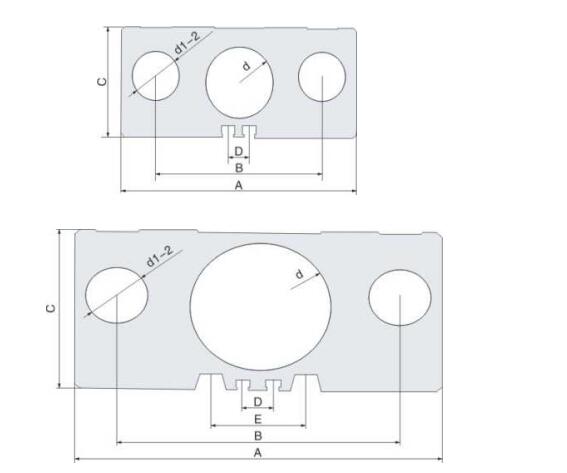

Dealbh sreath DFM

| NO | d | d1-2 | A | B | C | D | E |

| 1 | mu 12 | mu 11.5 | 60 | 41 | 28 | 10 | - |

| 2 | mu 16 | φ13 | 67 | 46 | 32 | 8.1 | - |

| 3 | φ20 | mu 15.5 | 83 | 58 | 36 | 10 | - |

| 4 | mu 25 | mu 17.5 | 95 | 68 | 44 | 10 | - |

| 5 | mu 32 | φ20 | 110 | 78 | 49 | 10 | - |

| 6 | φ40 | φ22.5 | 120 | 88 | 54 | 13.5 | - |

| 7 | φ50 | 27.5 | 148 | 110 | 64 | 16 | 40.5 |

| 8 | mu 63 | 27.5 | 162 | 125 | 78 | 13.5 | 42 |

Stuth de phròifil alloy alùmanum tiùb siolandair giuthais alùmanum: alloy alùmanum 6063 T5

Is e an Faid àbhaisteach againn 2000mm, ma tha feum air fad eile, feuch an cuir thu fios thugainn gu saor.

Uachdar anodized: Tiùb a-staigh-15 ± 5μm Tiùb a-muigh-10 ± 5μm

Aonta ri dealbhadh FESTO, SMC, Airtac, Chelic msaa.

A rèir inbhe ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Air a chleachdadh airson siolandair àbhaisteach, siolandair teann, siolandair beag, siolandair slat dùbailte, siolandair sleamhnag, siolandair Clàr Sleamhnag, Gripper msaa Cuideachd airson cuid de siolandairean sònraichte.

Dèanamh ceimigeach:

| Co-dhèanamh ceimigeach | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Sònrachadh:

| dian teannachaidh (N/mm2) | Neart toraidh (N/mm2) | Ductility (%) | Cruaidh uachdar | Cruinneas trast-thomhas a-staigh | Giorrachadh a-staigh | Dìreach | Mearachd tighead |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Tolerance of Aluminium Alloy Tube:

| TORLERANCE OF ALUMINIUM ALLOY Tube | ||||||

| Meud toll | TORLACHD | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

Ceistean Cumanta:

Q1: Dè a th 'ann am modail DFM? A: ☆ Tha e àbhaisteach FESTO.Tha meud an tollaidh bho Dia12mm gu Dia100mm.

Sònrachadh:☆ Aonad dràibheadh is stiùiridh ann an aon taigheadas

☆ An-aghaidh torques agus feachdan taobhach

☆ Stiùireadh giùlan ball soilleir no ath-chuairteachadh

☆ Measgachadh farsaing de roghainnean sreap is ceangail

☆ Raon farsaing de dhreachan airson tagraidhean gnàthaichte

Q2: Ma cheannaicheas sinn an DFM, a bheil e comasach le anodizing airson an Aluminium 6063 T5 Cylinder Tube?

A: Chan eilear a ’moladh an siolandair giuthais seo a bhith air a oxidachadh, oir feumaidh an neach-ceannach a ghearradh e fhèin agus an uairsin a phròiseasadh agus an uairsin làimhseachadh ocsaidean a dhèanamh às deidh a cheannach.

Q3: Dè an fhaid ma tha sinn ag òrdachadhExtrusion alùmanum airson siolandairean giuthais?

A: Tha an fhaid 2 mheatair.

Q4: Feart DFM modail

A: ☆ Leis an draibhear treòraichte DFM, faodaidh tu cunntadh air stiùireadh mionaideach agus làn sùghadh de torques agus feachdan taobhach, còmhla ri dealbhadh làidir, teann.Tha e freagarrach airson clampadh, togail agus stad iarrtasan.

Q5: Wadtha an ùine lìbhrigidhmu dheidhinn Pròifil alùmanum airson siolandair adhair?

A: ☆Ma tha pìoban àbhaisteach, feumaidh ùine 50-60 latha obrach, ach ma tha airson na tiùban àbhaisteach, is e an ùine lìbhrigidh againn 15-20 latha obrach.